| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Runlai |

| Model Number : | 0Cr13Al4 |

| Certification : | ISO9001 ROHS |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T, Western Union, MoneyGram |

| Supply Ability : | 300 tons per month |

| Delivery Time : | 20~40 Days |

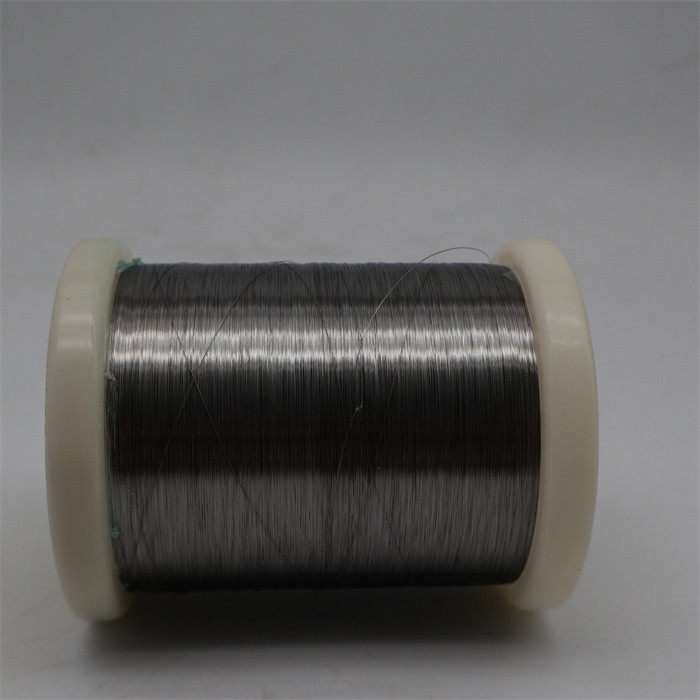

Good Corrosion Resistance Heating FeCrAl Electric Resistance Alloy Wire 1Cr13Al4 Wire

Product Introduction

1Cr13Al4 Wire is a high resistance electric heating alloy wire, the

main chemical composition is carbon content ≤0.12%, silicon content

≤0.7%, manganese content ≤0.5%, phosphorus content ≤0.025%, sulfur

content ≤0.02%, chromium content 12.0%~15.0%, nickel content ≤0.6%,

aluminum content 4.0%~6.0%, the balance is iron. It has good

corrosion resistance and high temperature strength, resistivity of

1.25±0.08μΩ·m, maximum use temperature up to 950℃, density of

7.40g/cm³.

This alloy wire is suitable for making electric heating elements

and industrial resistance elements in the temperature range of

950~1400℃, widely used in various industrial electric furnaces,

laboratory electric furnaces and electric heating elements of

household appliances, and also used in the aerospace field to

manufacture electric heating elements to ensure stable operation in

high temperature environment.

Parameter

| Shape | Size (mm) |

| Wire | 0.025-8.00mm |

| Rod | 8.00-50.00mm |

| Robbin | (0.05-0.35)*(0.5-6.0)mm |

| Strip | (0.50-2.50)*(5.00-180.00)mm |

| Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4/ 0Cr19Al3 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Main chemical composition | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Rest | opportune | opportune | opportune | opportune | opportune | opportune | opportune | |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

| Others | -- | -- | -- | -- | -- | Nb 0.5 | Mo 1.8-2.2 | |

| Max. continuous service temp. of element( °C ) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivity at 20ºC(μΩ@m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Thermal conductivity(KJ/m@h@ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | ||

| Line expansion coefficient(α×10-6/ºC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Melting point approx.( ºC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile Strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Elongation at break(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Repeat bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Hardness (H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| continuous service time(Hours/ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Specific Applications

Advantages and Characteristics

Contact Us

Email:fbwlau@cnrunlai.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

Our Nichrome Alloy product comes with technical support and services to ensure optimal performance and customer satisfaction:

We are committed to providing our customers with the highest level of support and service for our Nichrome Alloy product.

Product Packaging:

Shipping:

Related Questions and Answers

Q: What are the characteristics of 1Cr13Al4 Wire?

A: 1Cr13Al4 Wire has high resistivity, low temperature coefficient,

good oxidation resistance and high high temperature strength.

Q: What are the advantages of 1Cr13Al4 Wire?

A: The advantages of 1Cr13Al4 Wire include excellent corrosion

resistance, good mechanical properties, stable resistance

characteristics and high temperature stability.

Q: What are the physical properties of 1Cr13Al4 Wire?

A: The resistivity of 1Cr13Al4 Wire is 1.25±0.08μΩ·m, the maximum

operating temperature is 950℃, the melting point is about 1450℃,

the density is 7.40g/cm³, the mass heat capacity is 490J/(kg·K),

the thermal conductivity is 14.6W/(m·K), and the linear expansion

coefficient (20~1000℃) is 15.4×10⁻⁶/℃.

Q: What is the corrosion resistance of 1Cr13Al4 Wire?

Answer: When 1Cr13Al4 Wire is heated to 1000℃ in air, the surface

oxide scale is dense and can protect the alloy matrix. Therefore,

the thermoelectric potential of the alloy can remain unchanged

after long-term use.

|