| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Runlai |

| Model Number : | Monel 400 |

| Certification : | ISO9001 ROHS |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T, Western Union, MoneyGram |

| Supply Ability : | 300 tons per month |

| Delivery Time : | 20~40 Days |

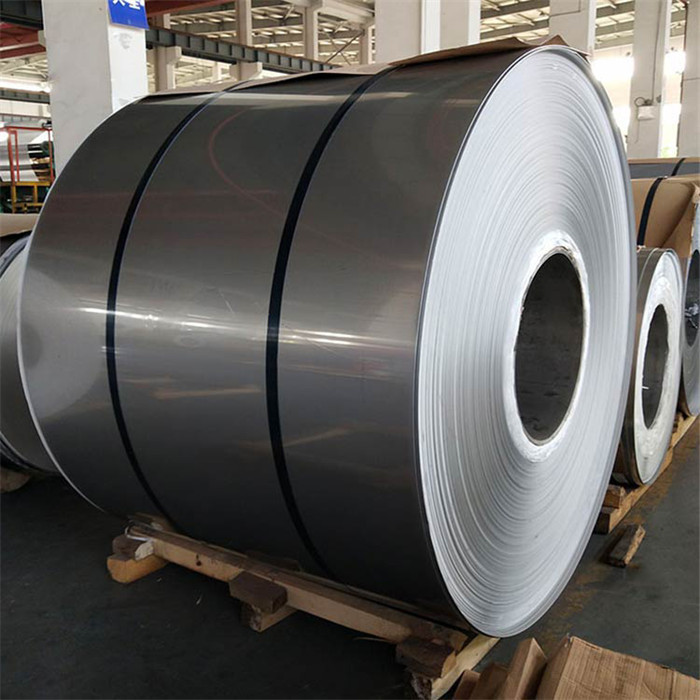

Monel400 Nickel Alloy Wire NO4400 Copper Nickel Alloy Wire 40% Elongation With Good Welding Performance

Product Introduction

Monel 400 strip is a high-performance nickel-based alloy strip with excellent strength and toughness, and it maintains good ductility even at low temperatures. It is a solid solution alloy that can achieve high strength properties by cold working hardening without aging hardening treatment. Monel 400 strip exhibits excellent corrosion resistance in a variety of reducing environments, especially in media such as seawater, hydrofluoric acid, sulfuric acid and hydrochloric acid. In addition, it has good resistance to stress corrosion cracking and pitting corrosion, and can operate stably for a long time in fresh water and industrial waters.

Monel 400 strip is widely used in oil and gas extraction, marine engineering, chemical and petrochemical processing and other fields. It can not only withstand extreme environmental conditions, but also maintain stable performance in the temperature range from cryogenic to 260°C. Whether it is used to manufacture complex mechanical parts or provide reliable solutions in highly corrosive environments, Monel 400 strip is an ideal choice.

Parameter

Diameter range: from 0.03 mm to 12 mm

Standard specifications: ASTM B164

Typical chemical composition: nickel (63% minimum), copper

(28-34%), iron (2.5% maximum), manganese (2.0% maximum), carbon

(0.3% maximum), etc.

Typical mechanical properties: tensile strength 550 MPa (minimum),

yield strength 240 MPa (minimum), elongation at break 40% (minimum)

Item | Ni | Cu | Fe | Mn | C | Si | S |

Monel 400 | ≥63 | 28-34 | ≤2.5 | ≤2 | ≤0.3 | ≤0.5 | ≤0.025 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation | HB |

Monel 400 | 8.83 g/cm3 | 1300-1390℃ | 480 | 170 | 35% | ≥331 |

Monel 400 | Bar/Rod | Forging | Pipe | Sheet/Strip | Welding Wire |

Standard | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ErNiCu-7 |

| AMS Number | Alloy | Type | UNS | Cross Ref. Spec | Misc./Shape |

|---|---|---|---|---|---|

| AMS 4544 Plate | Monel 400 | Nickel Copper | N04400 | QQ-N-281 | Plate |

| AMS 4544 Sheet | Monel 400 | Nickel Copper | N04400 | QQ-N-281 | Sheet |

| AMS 4544 Strip | Monel 400 | Nickel Copper | N04400 | QQ-N-281 | Strip |

| AMS 4574 | Monel 400 | Nickel Copper | N04400 | - | Tubing |

| AMS 4675 Bar | Monel 400 | Nickel Copper | N04400 | ASTM B 164 | Bar |

| AMS 4730 | Monel 400 | Nickel Copper | N04400 | QQ-N-281 | Wire |

| AMS 4731 Ribbon | Monel 400 | Nickel Copper | N04400 | - | Ribbon |

| AMS 4731 Wire | Monel 400 | Nickel Copper | N04400 | - | Wire |

Size Range (mm) | |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.50-2.5)*(5-180) |

Tube | custom made |

Plate | custom made |

Specific Applications

Advantages and Characteristics

Contact Us

Email:fbwlau@cnrunlai.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

Related Questions and Answers

1. What is Monel 400 Strip made of?

Monel 400 Strip is a nickel-copper based alloy, mainly composed of nickel (Ni) and copper (Cu), with high strength and good ductility.

2. What are the main application areas of Monel 400 Strip?

Monel 400 Strip is widely used in marine, chemical, petroleum and other fields, especially suitable for high temperature and corrosive environments such as seawater treatment equipment, heat exchangers, pump shafts, etc.

3. What is the processing performance of Monel 400 Strip?

Monel 400 Strip has good cold working performance, and its mechanical properties can be improved by cold working, but intermediate annealing is required to eliminate stress.

4. What is the heat treatment process of Monel 400 Strip?

The heat treatment of Monel 400 Strip is usually carried out in the temperature range of 700 to 900°C (1300 to 1650°F), and the recommended temperature is about 825°C (1510°F). Rapid air cooling or water quenching is recommended.

|