| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Runlai |

| Model Number : | ERNiCu-7 |

| Certification : | CE,ROHS,ISO 9001 |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T, Western Union, MoneyGram |

| Supply Ability : | 300 tons per month |

| Delivery Time : | 20~40 Days |

Marine Engineering ERNiCu-7 Grade Nickel Alloy Welding Wire With Good Welding Performance

Product Introduction

ERNiCu-7 welding wire is a nickel copper alloy welding wire known

for its excellent corrosion resistance and good mechanical

properties, particularly suitable for various applications in

marine engineering. The chemical composition of ERNiCu-7 welding

wire mainly includes 62% to 69% nickel and 18.81% to 36.5% copper,

which has good welding performance and corrosion resistance.This

welding wire is mainly used for welding and repairing key

structures such as offshore platforms, ships, and subsea pipelines.

Due to its excellent resistance to seawater corrosion, ERNiCu-7 can

effectively resist chloride ion erosion in seawater.

In marine environments, ERNiCu-7 welding wire not only provides

excellent corrosion resistance, but also has good conductivity and

thermal conductivity, making it an ideal welding material. In

addition, this welding wire is also suitable for welding dissimilar

materials and can form a strong connection between different

metals. This characteristic makes ERNiCu-7 have important

application value in the manufacturing and maintenance of marine

equipment, which can significantly extend the service life of the

equipment and reduce maintenance costs.

Parameter

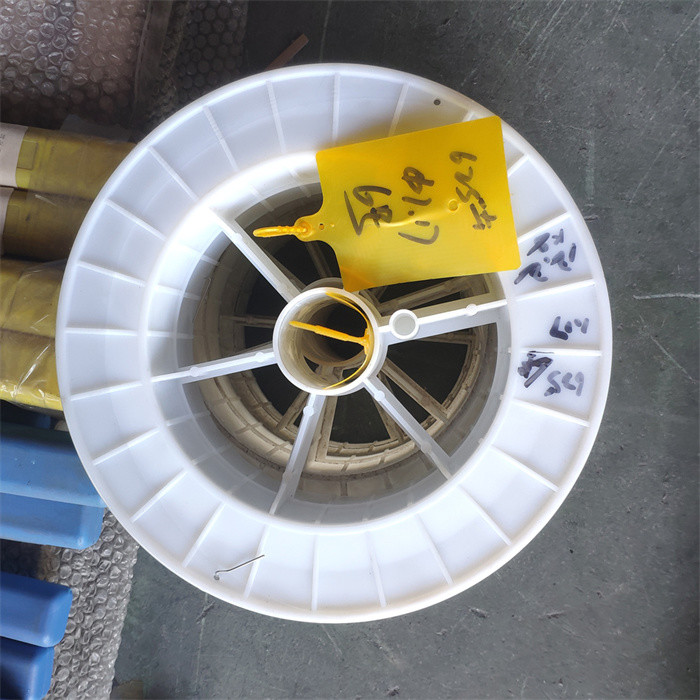

| MIG | (15kg/spool), | Size |

| 0.8 1.2 2.4 3.2mm | ||

| TIG | (5kg/box),Strip |

| C | Si | Mn | Cr | P | Ni |

| ≤0.01 | ≤0.2 | ≤0.5 | 22.0-24.0 | ≤0.015 | Rem |

| Al | Mo | Fe | Cu | S | Co |

| 0.10-0.40 | 15.0-16.50 | ≤0.5 | ≤0.1 | <0.01 | <0.20 |

| Typical Welding Parameters | |||||

| Diameter | Process | Volt | Amps (flat) | Amps (V/OH) | |

| inch | (mm) | ||||

| 0.035 | 0.9 | GMAW | 26-29 | 150-190 | Spray Transfer 100% Argon |

| 0.045 | 1.2 | GMAW | 28-32 | 180-220 | Spray Transfer 100% Argon |

| 1/16 | 1.6 | GMAW | 29-33 | 200-250 | Spray Transfer 100% Argon |

| 1/16 | 1.6 | GTAW | 14-18 | 90-130 | 100% Argon |

| 3/32 | 2.4 | GTAW | 15-20 | 120-175 | 100% Argon |

| 1/8 | 3.17 | GTAW | 15-20 | 150-220 | 100% Argon |

| Tensile Strength | 109 Ksi | 790 MPA |

| Yield Strength | 68 Ksi | 470 MPA |

| Elongation | 40-45% | |

| Density g/cm3 | 8.60 g/cm3 | |

| Melting Point ℃ | 1300-1360℃ | |

| Coefficient of Expansion. 21-93 Co, μm/m * Co | 11.90 |

Specific Applications

Advantages and Characteristics

The chemical composition of ERNiCu-7 welding wire mainly includes 62% to 69% nickel and 18.81% to 36.5% copper, which has good welding performance and corrosion resistance.

Contact Us

Email:fbwlau@cnrunlai.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

Customization

This is a series of welding wire products including ERNiCrMo-3, ERNiCrMo-4, ERNiCrMo-13, ERNiCrFe-3, ERNiCrFe-7, ERNiCr-3, ERNiCr-7, ERNiCu-7 and ERNi-1.

Nickel welding wire is available in different grades and specifications depending on specific application requirements. Various nickel alloy welding wires (such as ERNiCr-3, ERNiCrMo-3, etc.) and pure nickel welding wires (such as ERNi-1, ERNi-2, etc.) can be selected according to specific alloy composition and performance requirements.

In short, nickel welding wire is an important welding material with excellent welding performance and adaptability. It plays an important role in various industrial fields, providing reliable welding solutions for manufacturing and maintaining high-quality metal structures.

Q&A

Q: What are the chemical compositions of ERNiCu-7 welding wire?

Answer: The chemical composition of ERNiCu-7 welding wire mainly

includes about 62% nickel, about 30% copper, about 3% manganese,

about 1% titanium, etc.

Q: What materials are mainly welded with ERNiCu-7 welding wire in

marine engineering?

Answer: ERNiCu-7 welding wire is mainly used for welding Monel

alloy, Inconel alloy, as well as some stainless steel and carbon

steel materials in marine engineering.

Q: What is the welding performance of ERNiCu-7 welding wire?

Answer: ERNiCu-7 welding wire has good welding performance,

beautiful weld formation, good plasticity and toughness of the weld

metal, and is not prone to welding cracks.

Q: What are the precautions for using ERNiCu-7 welding wire?

Answer: When using ERNiCu-7 welding wire, attention should be paid

to controlling welding parameters such as welding current, voltage,

and welding speed to ensure the quality of the weld seam; At the

same time, the welding area should be kept clean during the welding

process to avoid contamination.

Q: Apart from marine engineering, what other fields are ERNiCu-7

welding wires suitable for?

Answer: ERNiCu-7 welding wire is also suitable for welding and

repair work in fields such as chemical equipment, oil and gas

pipelines, and food processing equipment, due to its excellent

corrosion resistance and welding performance.

|