| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Runlai |

| Model Number : | HC276 |

| Certification : | CE,ROHS,ISO 9001 |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T, Western Union, MoneyGram |

| Supply Ability : | 300 tons per month |

| Delivery Time : | 20~40 Days |

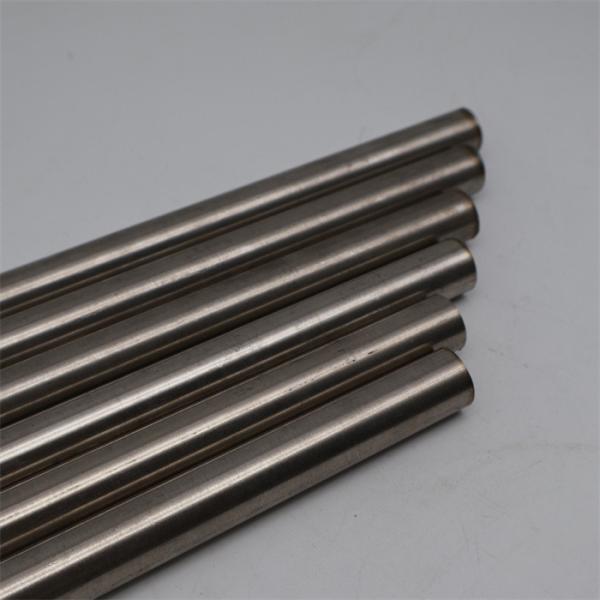

ASTM B564 W.Nr.2.4819 Black Bright Surface Hastelloy C276 Nickel Alloy Steel Bar/Rod with Excellent corrosion resistance

Product Introduction

Hastelloy C276 Rod is a high-performance nickel-based alloy widely used in the chemical industry. It has excellent corrosion resistance and can effectively resist the attack of chloride ions. It is particularly suitable for environments with strong acids, strong alkalis and complex media. Its high molybdenum and chromium content makes it perform well in oxidizing and reducing acids, while the low carbon content reduces the precipitation of carbides during welding and maintains the corrosion resistance of the welded structure. The physical properties of Hastelloy C276 Rod include density 8.9 g/cm³, melting point 1325-1370℃, tensile strength of at least 690 MPa, yield strength of at least 310 MPa, and elongation of at least 40%. This alloy has excellent processing performance, can be hot-worked and cold-worked, and is suitable for a variety of traditional welding processes. In the chemical industry, Hastelloy C276 Rod is often used to manufacture equipment such as reactors, heat exchangers, distillation towers, etc., especially when dealing with highly corrosive media such as high-concentration sulfuric acid and hydrochloric acid.

Parameter

| Hastelloy Alloy | Ni | Cr | Co | Mo | FE | W | Mn | C | V | P | S | Si |

| C276 | Balance | 14.5-16.5 | 2.5 Max | 15.0-17.0 | 4.0-7.0 | 3.0-4.5 | 1.0 Max | 0.01 Max | 0.35 Max | 0.04 Max | 0.03 Max | 0.08 Max |

| Hastelloy C276 Mechanical Properties (Minimum value at 20℃) | ||

| Tensile Strength (σb/MPa) | Yield Strength (σp0.2/MPa) | Elongation (σ5/%) |

| 996 | 549 | 30 |

| Hastelloy | Density g/cm3 | Melting point ℃ | Elongation A5 % | Tensile Strength Rm N/mm2 | Yield Strength RP0.2N/mm2 |

| C-276 | 8.9 | 1325-1370℃ | 62 | 758 | 363 |

| C-22 | 8.9 | 1325-1370 ℃ | 40 | 690 | 283 |

| C-2000 | 8.5 | 1399℃ 2550°F | 45 | 690 | 283 |

| B-2 | 9.2 | 1330-1380℃ | 40 | 745 | 325 |

| B-3 | 9.22 | 1370-1418℃ | 40 | 760 | 350 |

| G-30 | 8.22 | 1399℃ 2550°F | 62 | 524 | 200 |

| X | 8.3 | 1260-1355℃ | 30 | 690 | / |

| C-4 | 8.64 | 399°C 2550°F | 40 | 690 | 280 |

| G-35 | 8.22 | 1370-1400℃ | / | / | / |

| C | 8.94 | 1330-1380 ℃ | 40 | 690 | 310 |

| ASTM | Alloy | Type | UNS | Misc./Shape |

| ASTM B574 Bar | Hastelloy C276 | Nickel | N10276 | Bar |

| ASTM B575 Plate | Hastelloy C276 | Nickel | N10276 | Plate |

| ASTM B575 Strip | Hastelloy C276 | Nickel | N10276 | Strip |

| ASTM B575 Sheet | Hastelloy C276 | Nickel | N10276 | Sheet |

| ASTM B619 Welded Pipe | Hastelloy C276 | Nickel | N10276 | Welded Pipe |

| ASTM B622 Seamless Tubing | Hastelloy C276 | Nickel | N10276 | Seamless Tubing |

| ASTM B366 Fittings | Hastelloy C276 | Nickel | N10276 | Fittings |

| ASTM B574 Wire | Hastelloy C276 | Nickel | N10276 | Wire |

Specific Applications

Advantages and Characteristics

Contact Us

Email:fbwlau@cnrunlai.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

Q&A

Q: What are the main application areas of Hastelloy C276 rod?

A: Hastelloy C276 rod is widely used in chemical, oil and gas,

pharmaceutical, pulp and paper, and marine engineering. Specific

applications include the manufacture of high-temperature and

high-pressure equipment, reactors, heat exchangers, distillation

towers, aircraft and rocket parts, engine parts, etc.

Q: What are the characteristics of Hastelloy C276 rod?

A: Hastelloy C276 rod has excellent corrosion resistance and high

temperature resistance, and can form a dense oxide film under high

temperature environment, effectively preventing further oxidation.

It has high tensile strength and yield strength, and has good

plasticity and toughness. In addition, Hastelloy C276 rod also has

excellent oxidation resistance and reduction resistance, and can be

used in various high-temperature corrosion environments.

Q: What is the corrosion resistance of Hastelloy C276 rod?

A: Hastelloy C276 rod has excellent corrosion resistance to most

corrosive media in both oxidized and reduced states. Excellent

resistance to pitting corrosion, crevice corrosion and stress

corrosion cracking, making it resistant to chloride ion corrosion

and suitable for various chemical process industries containing

oxidizing and reducing media.

|